Poly(methyl vinyl ether-alt-maleic anhydride)CAS9011-16-9

specification

|

ITEM |

SPECIFICATIONS |

|

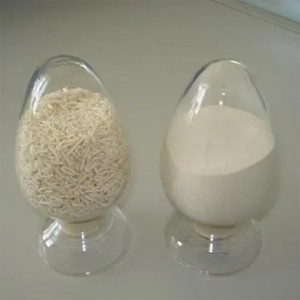

Appearance |

White or off - white powder |

|

Density |

1.37 |

|

Intrinsic viscosity SV (1% methyl ethyl ketone solution) |

0.1-0.5/0.5-1.0/1.0-1.5/1.5-2.5/2.5-4.0 |

|

LOD max |

≤2% |

|

Content of active substances |

≥98% |

|

Residual maleic anhydride |

ND |

|

CONCLUSION |

THE RESULTS CONFORMS WITH ENTERPRISE STANDARDS |

Usage

The methyl vinyl ether - maleic anhydride copolymer (PVME - MA) is widely used in various fields due to its unique chemical structure and properties:

1.Pharmaceutical Field:

- Drug Sustained - release Carrier: PVME - MA can form a gel structure to encapsulate drugs. After oral administration, in the gastrointestinal tract, it can slowly release the drugs according to the change of environmental pH value, thus prolonging the efficacy of the drugs. For example, some drugs for treating chronic diseases achieve precise and long - term release with the help of this copolymer.

- Tablet Coating Material: It is used for tablet coating to improve the moisture resistance and stability of drugs and control the drug release rate. At the same time, this copolymer has good biocompatibility and will not cause adverse reactions to the human body.

2.Cosmetics Field:

- Thickener: It can increase the viscosity of the cosmetic system, improve the product texture, making lotions, creams, etc. easier to apply. Moreover, it remains stable during storage and prevents the separation of components.

- Film - forming Agent: It forms a protective film on the skin surface, helps the skin retain moisture, and enhances the moisturizing effect of skin care products. In addition, it can also be used in products such as hairspray to provide a styling function.

3.Coating Field:

- Adhesion Promoter: When added to the coating, it can react chemically with the surface of the substrate, enhancing the adhesion between the coating and the substrate, making the coating more firm and less likely to fall off. It is commonly used in the painting of materials such as metals and plastics.

- Cross - linking Agent: By undergoing a cross - linking reaction with other components in the coating, it improves the hardness, wear resistance, and chemical corrosion resistance of the coating, enhancing the overall performance of the coating.

4.Paper - making Industry:

- Sizing Agent: It can form a protective film on the surface of paper, reducing the water absorption of paper and improving the water - resistant performance of paper. It is widely used in the production of packaging paper, writing paper, etc.

- Strength Enhancer: It interacts with paper fibers, increasing the binding force between fibers and improving the strength of paper, such as tensile strength and tear strength.

5.Oilfield Chemicals Field:

- Drilling Fluid Additive: It can adjust the rheology of the drilling fluid, form a filter cake on the wellbore wall, control the fluid loss, stabilize the wellbore wall, prevent formation collapse, and ensure the smooth progress of drilling operations.

- Oil Displacing Agent: After being injected into the oil reservoir, it can improve the oil displacement efficiency. By changing the oil - water interfacial tension, it makes the crude oil easier to be displaced from the rock pores, thus increasing the crude oil recovery rate.

Packaging and Shipping

20KG/Drum or as customer requirements.

Belongs to common goods and can deliver by ocean and air

Keep and storage

Shelf life:24 month from date of manufacture in original unopened packaging stored in a cool dry place out of direct sunlight, water.

Ventilated warehouse, Low temperature drying, Separated from oxidants, acids.